Industrial hygiene software digitalizes and automates exposure monitoring, data collection, and reporting processes. It supports industrial hygienists by organizing sampling plans, enabling mobile data capture, and automatically comparing results to regulatory limits. This approach improves data accuracy, streamlines workflows, and accelerates compliance with health and safety regulations.

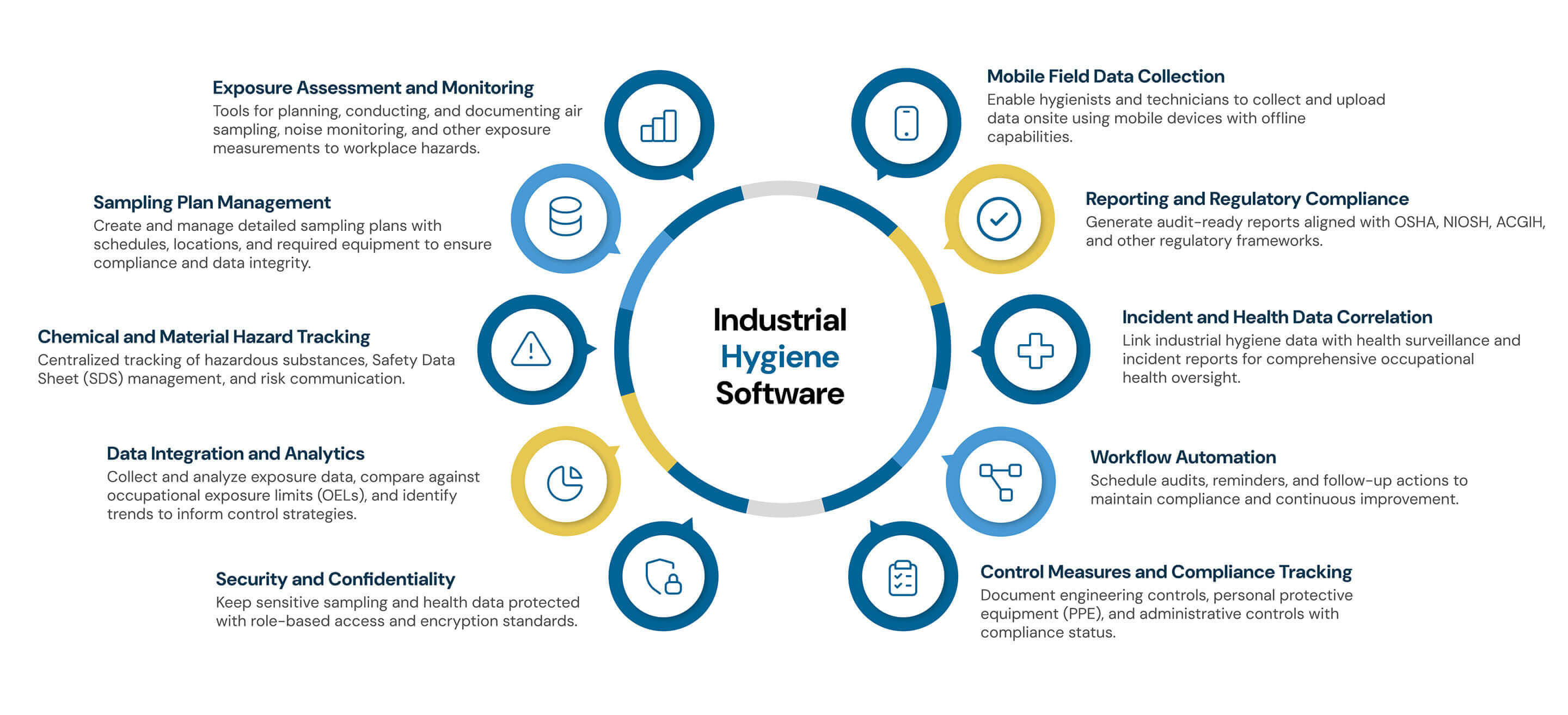

Key Features Buyers Should Look For in Industrial Hygiene Software

Exposure Assessment and Monitoring

Tools for planning, conducting, and documenting air sampling, noise monitoring, and other exposure measurements to workplace hazards.

Data Integration and Analytics

Collect and analyze exposure data, compare against occupational exposure limits (OELs), and identify trends to inform control strategies.

Reporting and Regulatory Compliance

Generate audit-ready reports aligned with OSHA, NIOSH, ACGIH, and other regulatory frameworks.

Security and Confidentiality

Keep sensitive sampling and health data protected with role-based access and encryption standards.

Sampling Plan Management

Create and manage detailed sampling plans with schedules, locations, and required equipment to ensure compliance and data integrity.

Control Measures and Compliance Tracking

Document engineering controls, personal protective equipment (PPE), and administrative controls with compliance status.

Incident and Health Data Correlation

Link industrial hygiene data with health surveillance and incident reports for comprehensive occupational health oversight.

Chemical and Material Hazard Tracking

Centralized tracking of hazardous substances, Safety Data Sheet (SDS) management, and risk communication.

Mobile Field Data Collection

Enable hygienists and technicians to collect and upload data onsite using mobile devices with offline capabilities.

Workflow Automation

Schedule audits, reminders, and follow-up actions to maintain compliance and continuous improvement.

IsoMetrix Industrial Hygiene Monitoring Solution

IsoMetrix Industrial Hygiene Solution Overview

Identify Industrial Hygiene Hazards

Consolidate incident reports, observations, exposure measurements, and environmental monitoring data so you can systematically spot health-related hazards across sites and operations. Configurable forms and workflows help teams capture field data on noise, dust, chemicals, heat, and ergonomics in a consistent way, creating a clear picture of where worker health may be at risk.

Common industrial hygiene hazards include:

- Chemical exposures such as solvents, welding fumes, cleaning agents, and process gases. These can lead to respiratory disease, skin irritation, and long-term systemic effects.

- Physical hazards like excessive noise, vibration, extreme heat or cold, and non-ionizing or ionizing radiation.

- Biological agents, including bacteria, viruses, mold, and allergens in healthcare, food, waste, and damp environments.

- Ergonomic risks from repetitive motions, awkward postures, manual handling, and poorly designed workstations that drive musculoskeletal disorders.

Assess Risks and Exposures

Enable structured risk and exposure assessments by linking each hazard to locations, similar exposure groups, job roles, and tasks. Risk scoring, configurable matrices, and analytics help you evaluate likelihood and severity, prioritize exposure scenarios, and document rationale for decisions in a transparent way.

Teams can:

- Build and manage exposure groups, sampling plans, and qualitative exposure assessments in one system.

- Combine monitoring data (e.g., noise dosimetry, air sampling) with task and job information to evaluate whether exposures are within acceptable limits.

- Use dashboards to highlight hotspots—areas, shifts, or roles where risk scores or exposure levels are trending upward.

Develop and Manage Control Measures

Once risks are understood, translate findings into practical controls and action plans. Connect hazards and exposure assessments to corrective and preventive actions, engineering and administrative controls, and PPE requirements, ensuring nothing falls through the cracks.

You can:

- Define and track controls for each hazard (e.g., ventilation upgrades, enclosure of noisy equipment, substitution of chemicals, rotation of staff, ergonomic redesign).

- Assign owners, due dates, and budgets to actions, with automated notifications and escalations to keep implementation on track.

- Document effectiveness checks and link them to inspections, exposure results, and health surveillance data for a closed-loop control process.

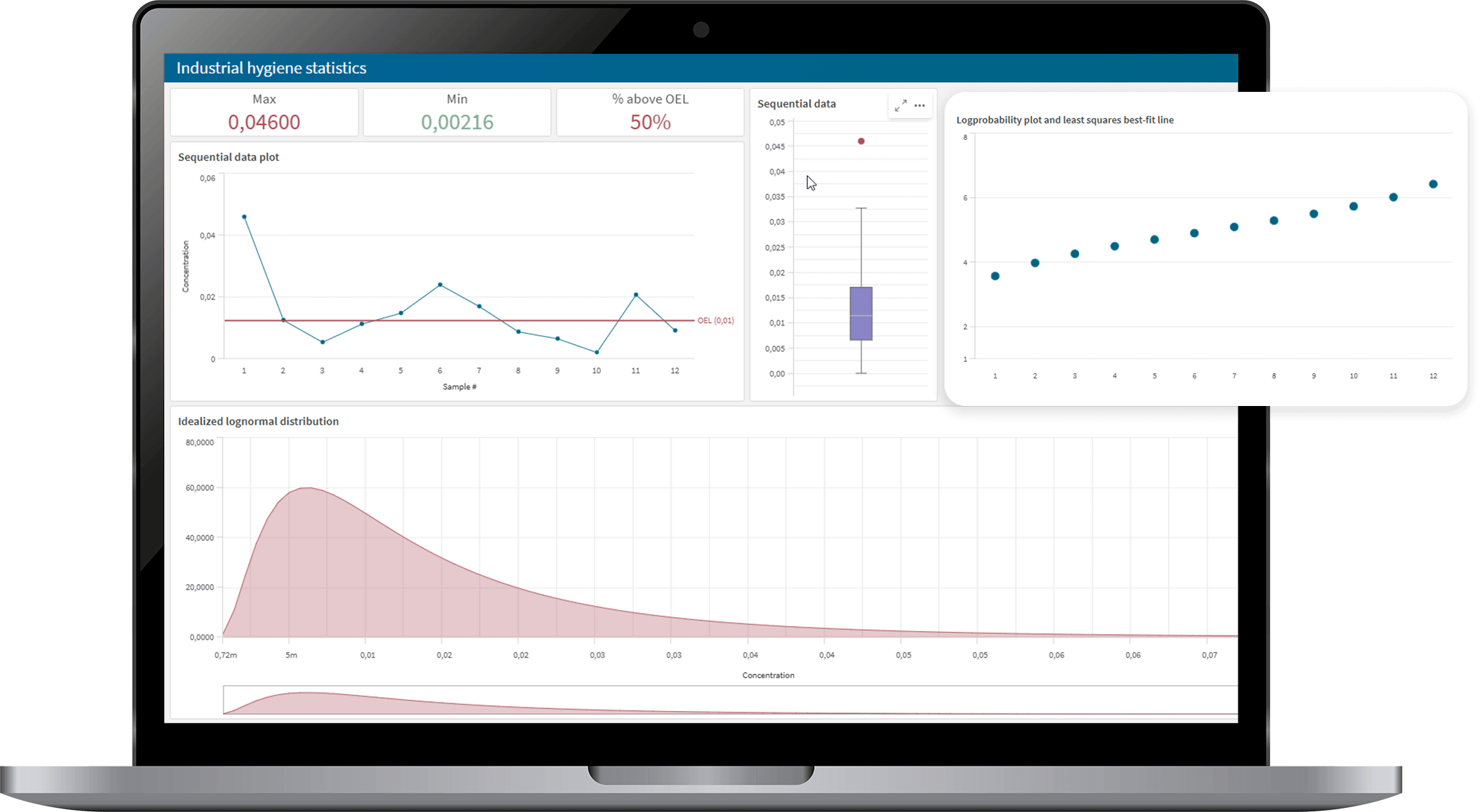

Monitor, Analyze, and Continuously Improve

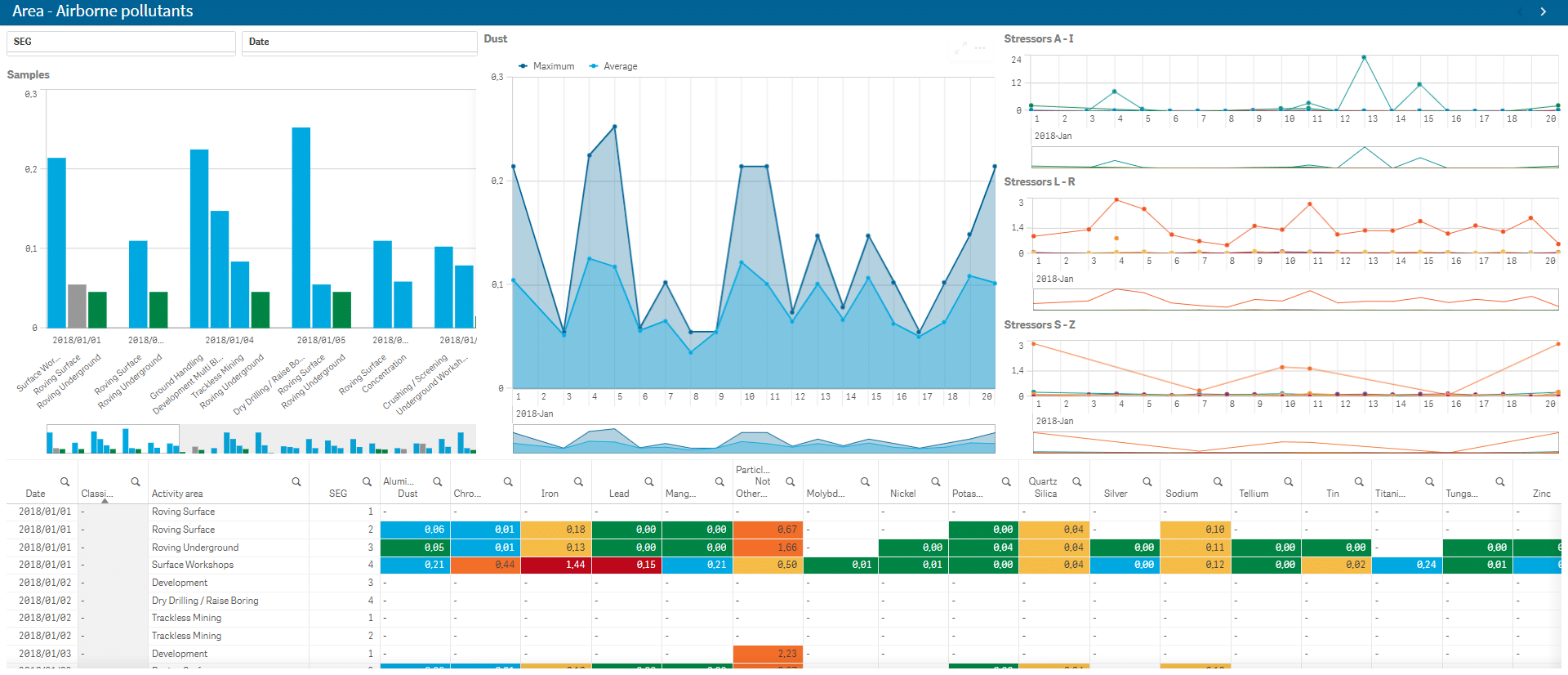

IsoMetrix’s analytics, dashboards, and reporting provide continuous oversight of industrial hygiene performance across your operations. Real-time and scheduled views help leaders track exposure trends, control status, and leading indicators so they can intervene early and demonstrate compliance with standards like ISO 45001 and occupational health regulations.

Key monitoring capabilities include:

- Aggregating sensor data, sampling results, and inspection findings to show trends for noise, air contaminants, heat stress, and other exposures.

- Visual dashboards that highlight overdue sampling, high-risk exposure groups, and sites where controls are not yet implemented or verified.

- Audit-ready records and configurable reports to support regulators, insurers, and internal stakeholders, reducing time spent compiling evidence from multiple systems.

With IsoMetrix, industrial hygiene becomes an integrated part of your broader EHS and risk strategy—helping you protect worker health, meet regulatory expectations, and build a more resilient, sustainable operation.

Why Choose IsoMetrix for Industrial Hygiene Software

Download Brochure

Health and Hygiene Software Solutions for High-Risk Industries

Health and Hygiene Software Solutions help to protect workers by systematically managing exposure, risk assessments, and regulatory compliance. It centralizes monitoring, medical surveillance, and analytics, while automating corrective actions and inspections.