International Manufacturing and Services Company - Customer Story

The Challenge

The Global Director of Safety and Sustainability at a publicly traded international manufacturing and services company had finally decided that relying primarily on Excel, shared folders, and email was no longer a viable way to manage sustainability reporting for the business.

For the past five years, he had been providing disclosures to multiple sustainability reporting standards and frameworks, including CDP and GRI, across four major business units. With over 200 locations in eight countries, the Director had to navigate many different systems and procedures making the task to report incredibly time consuming.

The Evaluation

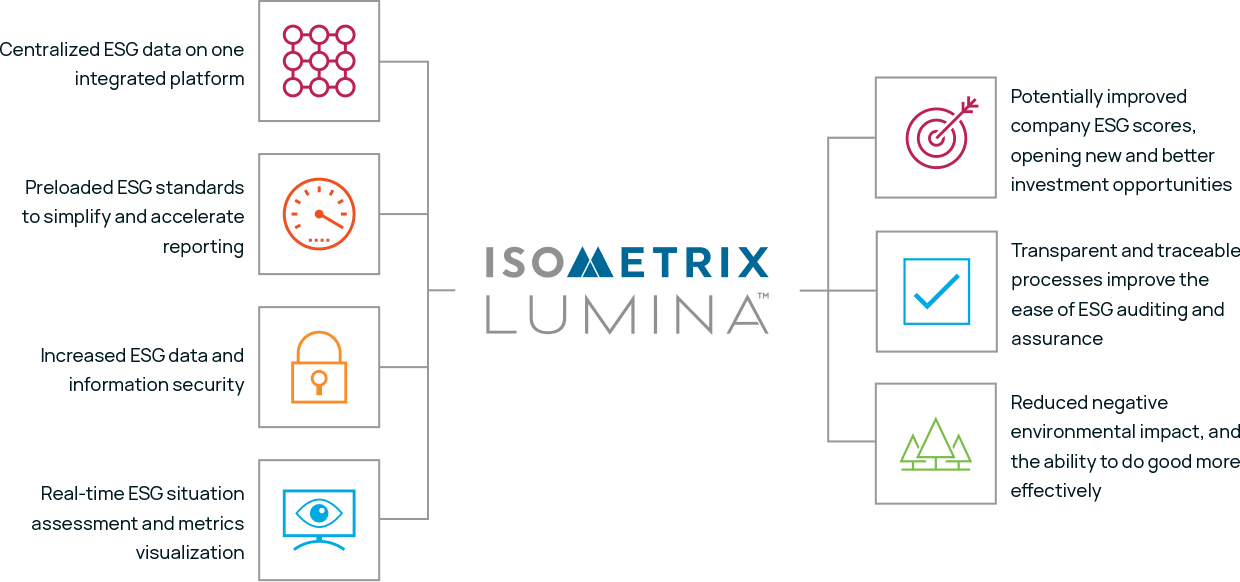

“I just want to be able to get sustainability data into a single place without having to send a million emails,” lamented the Global Director of Safety and Sustainability in a meeting with IsoMetrix. When evaluating sustainability management software solutions, there needed to be methods for collecting both HR and environmental data that could be calculated into GHG emissions.

What impressed the Director was Lumina’s versatility to gather data with multiple automated and semi-automated methods like API integrations, spreadsheet uploads, and digital forms. Another benefit was improved auditability with the ability to include attachments and view change history and calculations for every data point.

Data analysis has also improved with better performance visibility at every level of the manufacturing company, helping to inform business strategy.

The Results

The Director’s first initiative with IsoMetrix Lumina was to import historical data from spreadsheets. Lumina’s ability to map columns to the right data categories using AI made the

process very easy.

Next on the task list was to create schedules for digital forms for automatic distribution to data owners and collaborators across the business on monthly and quarterly bases, so they could easily submit information and supporting attachments. The Director found it particularly helpful that Lumina would handle grid (including eGRID) conversion factors for all eight countries he oversaw.

Reporting to sustainability standards and frameworks has gotten significantly easier since adopting Lumina to manage sustainability, and reports can now be produced in minutes rather than days. Data analysis has also improved with better performance visibility at every level of the manufacturing company, helping to inform business strategy.

Having used IsoMetrix Lumina for over a year and a half, the Director has seen significant growth in product capabilities, including implementation of suggestions he personally made to the product team. Improvements, such as the ability to customize reporting periods and create calculations to automate estimates and ratios have helped to make reporting more accurate in even less time.